Factory directly supply Polypropylene Injection Molding Process - BIO PLA RESIN-REVO DE110 FOR EXTURSION – Chemdo

Factory directly supply Polypropylene Injection Molding Process - BIO PLA RESIN-REVO DE110 FOR EXTURSION – Chemdo Detail:

Product Parameters

Product: Poly Lactic Acid

Chemical Formula: (C4H6O3)x

Cas No: 31852-84-3

Print Date: May 10th, 2020

Description

Poly lactic acid resin, made from corn and other plants rich in starch rather than oil, is a low-carbon functional material with superior processing properties.

Packaging

In 25kg kraft bag

|

ITEMS |

UNIT |

METHOD |

REVO |

REVO |

REVO |

REVOD |

|

|

Density |

g/cm³ |

GB/T1033.1-2008 |

1.2-1.3 |

1.2-1.3 |

1.2-1.3 |

1.2-1.3 |

|

|

MVR 190℃,2KG |

g/10 min |

GB/T 3682.1-2018 |

2-10 |

3-12 |

2-12 |

12-40 |

|

|

Melting Points |

℃ |

GB/T19466.3-2004 |

140-155 |

155-170 |

170-180 |

170-180 |

|

|

Glasstransition temperature |

℃ |

GB/T19466.2-2004 |

56-60 |

56-60 |

56-60 |

56-60 |

|

|

Tensile Strengh |

Mpa |

GB/T1040.1-2018 |

≥50 |

≥50 |

≥50 |

≥50 |

|

|

Elongation At Break |

% |

GB/T1040.1-2018 |

≥3.0 |

≥3.0 |

≥3.0 |

≥3.0 |

|

|

Notch impact strength |

KJ/m2 |

GB/T1040.1-2018 |

≥1-3 |

≥2.0 |

≥2.0 |

≥2.0 |

|

Product Details

Polylactic Acid (PLA) is made from renewable green eco-friendly bioplastic polymer, which is typically produced through the extraction and fermentation of starch from plants such as corn, sugar beets, cassava and sugarcane. PLA is biodegradable under commercial composting conditions and will breakdown within twelve weeks, making it a more environmentally choice when it comes to plastics in contrast to traditional plastics which could take centuries to decompose and end up creating microplastics.

The manufacturing process for PLA is also more environmentally friendly than that of traditional plastics made from finite fossil resources. According to research, the carbon emissions associated with PLA production are 80% lower than that of traditional plastic (source).

REVODE110 Can Be Applied To

Extrusion Blister products: Ransparent extrusion grade. The transparency, gloss and mechanical properties are close to those of pet, and the toughness is worse than that of pet. It is easy to match colors and print. It can be used in traditional extrusion equipment.

Film blowing and coating products: Blown film modified blend base material is used for film products requiring heat sealing and high transparency.

Fiber / non-woven products: Used for staple fiber and spunbonded non-woven products

Extrusion blow molding and injection blow molding products: It can directly produce transparent extrusion blowing and injection blowing

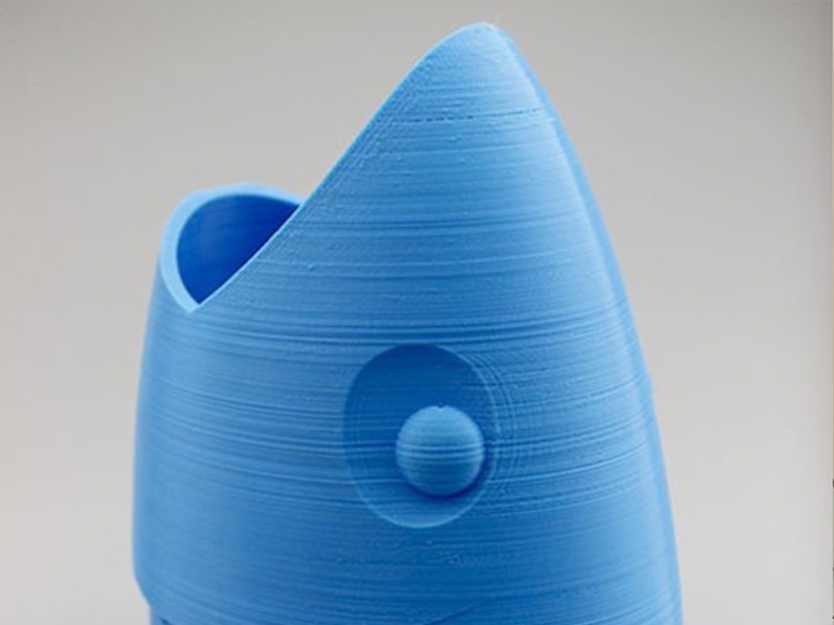

Manufacturing 3D printing additive: The special base material modified for 3D printing has good printing effect, edge warping, low shrinkage, non-toxic and odorless printing process

REVODE ® Product

Comply with the chemical substance control regulations of China, the United States, the European Union (REACH), Japan and other countries and regions.

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" plus the theory of "quality the basic, have faith in the main and management the advanced" for Factory directly supply Polypropylene Injection Molding Process - BIO PLA RESIN-REVO DE110 FOR EXTURSION – Chemdo , The product will supply to all over the world, such as: Slovenia, Irish, Zimbabwe, Since its foundation , the company keeps living up to the belief of "honest selling , best quality , people-orientation and benefits to customers. " We are doing everything to offer our customers with best services and best products . We promise that we'll be responsible all the way to the end once our services begin.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!