Hot New Products Polypropylene Homopolymer Material Socket Fusion Polypropylene - BIO PLA RESIN-REVO DE290 FOR INJECTION – Chemdo

Hot New Products Polypropylene Homopolymer Material Socket Fusion Polypropylene - BIO PLA RESIN-REVO DE290 FOR INJECTION – Chemdo Detail:

Product Parameters

Product: Poly Lactic Acid

Chemical Formula: (C4H6O3)x

Cas No: 31852-84-3

Print Date: May 10th, 2020

Description

Poly lactic acid resin, made from corn and other plants rich in starch rather than oil, is a low-carbon functional material with superior processing properties.

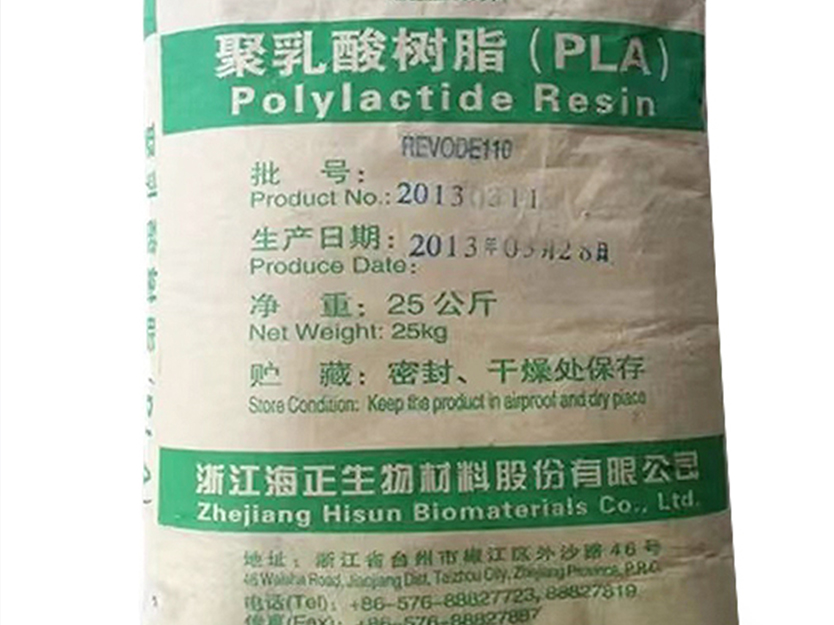

Packaging

In 25kg kraft bag

|

ITEMS |

UNIT |

METHOD |

REVO |

REVO |

REVO |

REVOD |

|

|

Density |

g/cm³ |

GB/T1033.1-2008 |

1.2-1.3 |

1.2-1.3 |

1.2-1.3 |

1.2-1.3 |

|

|

MVR 190℃,2KG |

g/10 min |

GB/T 3682.1-2018 |

2-10 |

3-12 |

2-12 |

12-40 |

|

|

Melting Points |

℃ |

GB/T19466.3-2004 |

140-155 |

155-170 |

170-180 |

170-180 |

|

|

Glasstransition temperature |

℃ |

GB/T19466.2-2004 |

56-60 |

56-60 |

56-60 |

56-60 |

|

|

Tensile Strengh |

Mpa |

GB/T1040.1-2018 |

≥50 |

≥50 |

≥50 |

≥50 |

|

|

Elongation At Break |

% |

GB/T1040.1-2018 |

≥3.0 |

≥3.0 |

≥3.0 |

≥3.0 |

|

|

Notch impact strength |

KJ/m2 |

GB/T1040.1-2018 |

≥1-3 |

≥2.0 |

≥2.0 |

≥2.0 |

|

Product Details

Polylactic acid (PLA) has the best tensile strength and ductility. PLA can also be produced by various common processing methods, such as melting extrusion molding, injection molding, film blowing molding, foaming molding and vacuum molding. It has similar forming conditions with widely used polymers. In addition, it also has the same printing performance as traditional films. In this way, polylactic acid can be made into a variety of application products according to the needs of different industries.

Lactic acid (PLA) film has good air permeability, oxygen permeability and carbon dioxide permeability. It also has the characteristics of isolating odor. Viruses and molds are easy to adhere to the surface of biodegradable plastics, so there are doubts about safety and hygiene. However, polylactic acid is the only biodegradable plastics with excellent antibacterial and mildew resistance.

When incinerating polylactic acid (PLA), its combustion calorific value is the same as that of incinerated paper, which is half of that of incinerating traditional plastics (such as polyethylene), and the incineration of PLA will never release toxic gases such as nitrides and sulfides. The human body also contains lactic acid in the form of monomer, which indicates the safety of this decomposition product.

REVODE290 Can Be Applied To

Injection molding products: Transparent injection molding grade. The melting point is high. It is used for injection molding transparent products or injection blowing products. It can also be used for base materials with high heat resistance modification.

REVODE ® Product

Comply with the chemical substance control regulations of China, the United States, the European Union (REACH), Japan and other countries and regions.

Product detail pictures:

Related Product Guide:

We intention to see quality disfigurement within the creation and supply the ideal support to domestic and overseas buyers wholeheartedly for Hot New Products Polypropylene Homopolymer Material Socket Fusion Polypropylene - BIO PLA RESIN-REVO DE290 FOR INJECTION – Chemdo , The product will supply to all over the world, such as: Lisbon, Albania, Liverpool, We look forward to hearing from you, whether you are a returning customer or a new one. We hope you will find what you are looking for here, if not, please contact us immediately. We pride ourselves on top notch customer service and response. Thank you for your business and support!

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.