Industry News

-

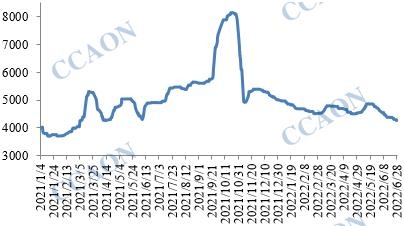

China’s PVC exports remain high in the first half of the year.

According to the latest customs statistics, in June 2022, my country’s import volume of PVC pure powder was 29,900 tons, an increase of 35.47% from the previous month and a year-on-year increase of 23.21%; in June 2022, my country’s PVC pure powder export volume was 223,500 tons, The month-on-month decrease was 16%, and the year-on-year increase was 72.50%. The export volume continued to maintain a high level, which alleviated the relatively abundant supply in the domestic market to a certain extent. -

What is Polypropylene (PP) ?

Polypropylene (PP) is a tough, rigid, and crystalline thermoplastic. It is made from propene (or propylene) monomer. This linear hydrocarbon resin is the lightest polymer among all commodity plastics. PP comes either as homopolymer or as copolymer and can be greatly boosted with additives. It finds application in packaging, automotive, consumer good, medical, cast films, etc. PP has become a material of choice, especially when you are looking for a polymer with superior strength (e.g., vs Polyamide) in engineering applications or simply looking for cost advantage in blow molding bottles (vs. PET). -

What is Polyethylene (PE) ?

Polyethylene (PE) , also known as polythene or polyethene, is one of the most commonly used plastics in the world. Polyethylenes usually have a linear structure and are known to be addition polymers. The primary application of these synthetic polymers is in packaging. Polyethelyne is often used to make plastic bags, bottles, plastic films, containers, and geomembranes. It can be noted that over 100 million tonnes of polyethene is produced on an annual basis for commercial and industrial purposes. -

Analysis of the operation of my country’s PVC export market in the first half of 2022.

In the first half of 2022, the PVC export market increased year-on-year. In the first quarter, affected by the global economic recession and the epidemic, many domestic export companies indicated that the demand for external disks was relatively reduced. However, since the beginning of May, with the improvement of the epidemic situation and a series of measures introduced by the Chinese government to encourage economic recovery, the operating rate of domestic PVC production enterprises has been relatively high, the PVC export market has warmed up, and the demand for external disks has increased. The number shows a certain growth trend, and the overall performance of the market has improved compared with the previous period. -

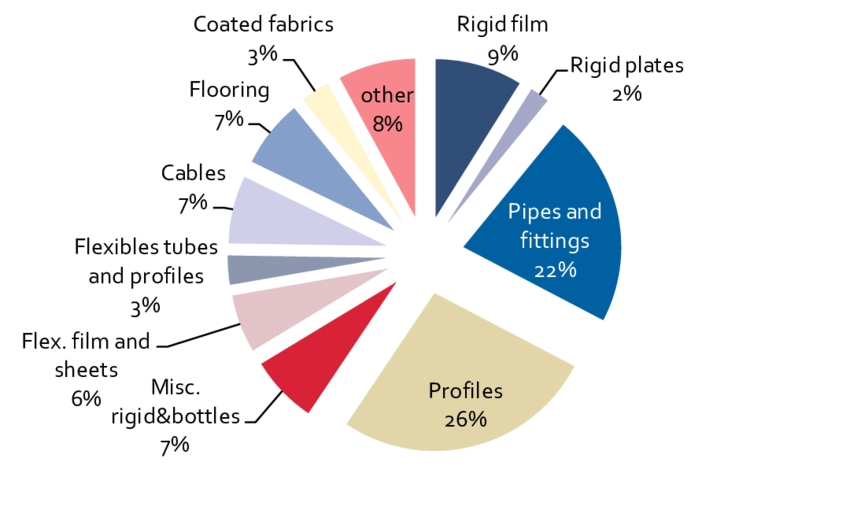

What PVC is used for ?

Economical, versatile polyvinyl chloride (PVC, or vinyl) is used in a variety of applications in the building and construction, health care, electronics, automobile and other sectors, in products ranging from piping and siding, blood bags and tubing, to wire and cable insulation, windshield system components and more. -

Hainan Refinery’s million-ton ethylene and refining expansion project is about to be handed over.

The Hainan Refining and Chemical Ethylene Project and the Refining Reconstruction and Expansion Project are located in Yangpu Economic Development Zone, with a total investment of more than 28 billion yuan. Up to now, the overall construction progress has reached 98%. After the project is completed and put into production, it is expected to drive more than 100 billion yuan of downstream industries. Olefin Feedstock Diversification and High-end Downstream Forum will be held in Sanya on July 27-28. Under the new situation, the development of large-scale projects such as PDH, and ethane cracking, the future trend of new technologies such as direct crude oil to olefins, and new generation of coal/methanol to olefins will be discussed. -

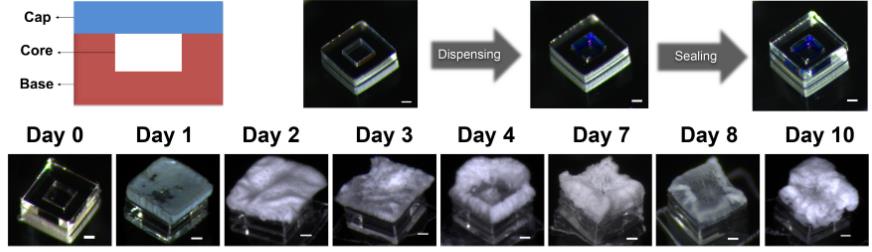

MIT: Polylactic-glycolic acid copolymer microparticles make “self-enhancing” vaccine.

Scientists at the Massachusetts Institute of Technology (MIT) report in the recent journal Science Advances that they are developing a single-dose self-boosting vaccine. After the vaccine is injected into the human body, it can be released multiple times without the need for a booster shot. The new vaccine is expected to be used against diseases ranging from measles to Covid-19. It is reported that this new vaccine is made of poly(lactic-co-glycolic acid) (PLGA) particles. PLGA is a degradable functional polymer organic compound, which is non-toxic and has good biocompatibility. It has been approved for use in Implants, sutures, repair materials, etc. -

Yuneng Chemical Company: First industrialized production of sprayable polyethylene!

Recently, the LLDPE unit of the Polyolefin Center of Yuneng Chemical Company successfully produced DFDA-7042S, a sprayable polyethylene product. It is understood that the sprayable polyethylene product is a product derived from the rapid development of downstream processing technology. The special polyethylene material with spraying performance on the surface solves the problem of poor coloring performance of polyethylene and has high gloss. The product can be used in decoration and protection fields, suitable for children’s products, vehicle interiors, packaging materials, as well as large industrial and agricultural storage tanks, toys, road guardrails, etc., and the market prospect is very considerable. -

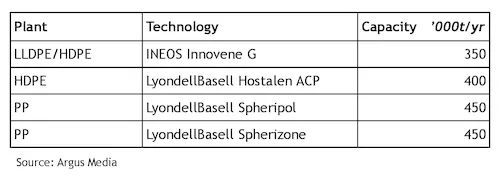

Petronas 1.65 million tons of polyolefin is about to return to the Asian market!

According to the latest news,Pengerang in Johor Bahru,Malaysia,has restarted its 350,000-ton/year linear low-density polyethylene (LLDPE) unit on July 4, but the unit may take a while to Achieve stable operation. Besides, its Spheripol technology 450,000 tons/year polypropylene (PP) plant, 400,000 tons/year high-density polyethylene (HDPE) plant and Spherizone technology 450,000 tons/year polypropylene (PP) plant are also expected to increase from this month to restart. According to Argus’ assessment, the price of LLDPE in Southeast Asia without tax on July 1 is US$1360-1380/ton CFR, and the price of PP wire drawing in Southeast Asia on July 1 is US$1270-1300/ton CFR without tax. -

Cigarettes switch to biodegradable plastic packaging in India.

India’s ban on 19 single-use plastics has prompted changes in its cigarette industry. Before July 1, Indian cigarette manufacturers had changed their previous conventional plastic packaging to biodegradable plastic packaging. The Tobacco Institute of India (TII) claims that their members have been converted and the biodegradable plastics used meet international standards, as well as the recently issued BIS standard. They also claim that the biodegradation of biodegradable plastics begins in contact with the soil and naturally biodegrades in composting without stressing solid waste collection and recycling systems. -

Brief Analysis of the Operation of Domestic Calcium Carbide Market in the First Half of the Year.

In the first half of 2022, the domestic calcium carbide market did not continue the wide fluctuation trend in 2021. The overall market was near the cost line, and it was subject to fluctuations and adjustments due to the impact of raw materials, supply and demand, and downstream conditions. In the first half of the year, there was no new expansion capacity of domestic calcium carbide method PVC plants, and the increase in calcium carbide market demand was limited. It is difficult for chlor-alkali enterprises that purchase calcium carbide to maintain a stable load for a long time. -

An explosion occurred in a PVC reactor of a petrochemical giant in the Middle East!

The Turkish petrochemical giant Petkim announced that on the evening of June 19, 2022, an explosion occurred at the Aliaga plant. the accident occurred in the factory’s PVC reactor, no one was injured, the fire was quickly under control, but the PVC unit may be temporarily offline due to the accident. The event may have a greater impact on the European PVC spot market. It is reported that because the price of PVC in China is much lower than that of Turkey’s domestic products, and the spot price of PVC in Europe is higher than that in Turkey, most of Petkim’s PVC products are currently exported to the European market.