Industry News

-

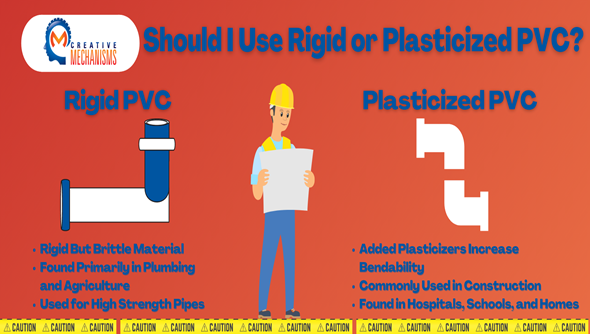

What are the Characteristics of Polyvinyl Chloride (PVC)?

Some of the most significant properties of Polyvinyl Chloride (PVC) are: Density: PVC is very dense compared to most plastics (specific gravity around 1.4) Economics: PVC is readily available and cheap. Hardness: Rigid PVC ranks well for hardness and durability. Strength: Rigid PVC has excellent tensile strength. Polyvinyl Chloride is a “thermoplastic” (as opposed to “thermoset”) material, which has to do with the way the plastic responds to heat. Thermoplastic materials become liquid at their melting point (a range for PVC between the very low 100 degrees Celsius and higher values like 260 degrees Celsius depending on the additives). A primary useful attribute about thermoplastics is that they can be heated to their melting point, cooled, and reheated again wi... -

What is caustic soda?

On an average trip to the supermarket, shoppers may stock up on detergent, purchase a bottle of aspirin and take a look at the latest headlines on newspapers and magazines. At first glance, it may not seem like these items have much in common. However, for each of them, caustic soda plays a key role in their ingredient lists or manufacturing processes. What is caustic soda? Caustic soda is the chemical compound sodium hydroxide (NaOH). This compound is an alkali – a type of base that can neutralize acids and is soluble in water. Today caustic soda can be manufactured in the form of pellets, flakes, powders, solutions and more. What is caustic soda used for? Caustic soda has become a common ingredient in the production of many everyday items. Commonly known as lye, it has been used t... -

Why is Polypropylene used so often?

Polypropylene is used in both household and industrial applications. Its unique properties and ability to adapt to various fabrication techniques make it stand out as an invaluable material for a wide range of uses. Another invaluable characteristic is polypropylene’s ability to function as both a plastic material and as a fiber (like those promotional tote bags that are given away at events, races, etc). Polypropylene’s unique ability to be manufactured through different methods and into different applications meant it soon started to challenge many of the old alternative materials, notably in the packaging, fiber, and injection molding industries. Its growth has been sustained over the years and it remains a major player in the plastic industry worldwide. At Creative Mechanisms, we ha... -

What are PVC granules ?

PVC is one of the most used plastics in the industry sector. Plasticol, an Italian company located near Varese has been manufacturing PVC granules for more than 50 years now and the experience accumulated over the years allowed the business to gain such a deep level of know-how that we can now use it to satisfy all the clients’ requests offering innovative and reliable products. The fact that PVC is widely used for the production of many different objects shows how its intrinsic characteristics are extremely useful and special. Let’s start talking about the rigidity of PVC: the material is very stiff if pure but it becomes flexible if mixed with other substances. This distinctive trait makes PVC suitable for the manufacturing of products used in different fields, from the building one t... -

Biodegradable glitter could revolutionize the cosmetics industry.

Life is full of shiny packaging, cosmetic bottles, fruit bowls and more, but many of them are made of toxic and unsustainable materials that contribute to plastic pollution. Recently, researchers at the University of Cambridge in the UK have found a way to create sustainable, non-toxic and biodegradable glitter from cellulose, the main building block of the cell walls of plants, fruits and vegetables. Related papers were published in the journal Nature Materials on the 11th. Made from cellulose nanocrystals, this glitter uses structural color to alter light to produce vibrant colors. In nature, for example, the flashes of butterfly wings and peacock feathers are masterpieces of structural color, which will not fade after a century. Using self-assembly techniques, cellulose can produce ... -

What is Polyvinyl chloride (PVC) paste Resin ?

Polyvinyl chloride (PVC) paste Resin , as the name implies, is that this resin is mainly used in paste form. People often use this type of paste as plastisol, which is a unique liquid form of PVC plastic in its unprocessed state. . Paste resins are often prepared by emulsion and micro-suspension methods. Polyvinyl chloride paste resin has a fine particle size, and its texture is like talc, with immobility. The polyvinyl chloride paste resin is mixed with a Plasticizer and then stirred to form a stable suspension, which is then made into PVC paste, or PVC plastisol, PVC sol, and it is in this form that people are used to process the final Products. In the process of making paste, various fillers, diluents, heat stabilizers, foaming agents and light stabilizers are added according to the ... -

What is PP Films ?

PROPERTIES Polypropylene or PP is a low cost thermoplastic of high clarity, high gloss and good tensile strength. It has a higher melting point than PE, which makes it suitable for applications that require sterilization at high temperatures. It also has less haze and higher gloss. Generally, the heat-sealing properties of PP are not as good as those of LDPE. LDPE also has better tear strength and low temperature impact resistance. PP can be metallized which results in improved gas barrier properties for demanding applications where long product shelf life is important. PP films are well suited for a broad range of industrial, consumer, and automotive applications. PP is fully recyclable and can be easily reprocessed into many other products for many different applications. However, unl... -

what is PVC compound ?

PVC compounds are based on the combination of the PVC polymer RESIN and additives that give the formulation necessary for the end-usage (Pipes or Rigid Profiles or Flexible Profiles or Sheets). The compound is formed by intimately mixing together the ingredients, which is subsequently converted into the “gelled” article under the influence of heat and shear force. Depending on the type of PVC and additives, the compound prior to gelation can be a free-flowing powder (known as a dry blend) or a liquid in the form of a paste or solution. PVC compounds when formulated, using plasticizers, into flexible materials, usually called PVC-P. PVC Compounds when formulated without plasticizer for rigid applications are designated PVC-U. PVC Compounding can be summed up as follows: The rigid PVC dr... -

Difference Between BOPP, OPP and PP Bags.

The food industry majorly uses BOPP plastic packaging. BOPP bags are easy to print, coat and laminate which makes them suitable for packing products like fresh produces, confectionaries and snacks. Alongwith BOPP, OPP, and PP bags are also used for packaging. Polypropylene is a common polymer among the three used for manufacturing the bags. OPP stands for Oriented Polypropylene, BOPP stands for Biaxially Oriented Polypropylene and PP stands for Polypropylene. All three differ in their style of fabrication. Polypropylene also known as polypropene is a thermoplastic semi-crystalline polymer. It is tough, strong and has high impact resistance. Standup pouches, spout pouches and ziplock pouches are made from polypropylene. It is very difficult to differentiate between OPP, BOPP and PP plas... -

Application Research of Concentrating Light (PLA) in LED Lighting System.

Scientists from Germany and the Netherlands are researching new environmentally friendly PLA materials. The aim is to develop sustainable materials for optical applications such as automotive headlights, lenses, reflective plastics or light guides. For now, these products are generally made of polycarbonate or PMMA. Scientists want to find a bio-based plastic to make car headlights. It turns out that polylactic acid is a suitable candidate material. Through this method, scientists have solved several problems faced by traditional plastics: first, turning their attention to renewable resources can effectively alleviate the pressure caused by crude oil on the plastics industry; second, it can reduce carbon dioxide emissions; third, this Involves consideration of the entire material life c... -

Luoyang million tons of ethylene project made new progress !

On October 19, the reporter learned from Luoyang Petrochemical that Sinopec Group Corporation held a meeting in Beijing recently, inviting experts from more than 10 units including China Chemical Society, China Synthetic Rubber Industry Association, and relevant representatives to form an evaluation expert group to evaluate millions of Luoyang Petrochemical. The feasibility study report of the 1-ton ethylene project will be comprehensively evaluated and demonstrated. At the meeting, the evaluation expert group listened to the relevant reports of Luoyang Petrochemical, Sinopec Engineering Construction Company and Luoyang Engineering Company on the project, and focused on a comprehensive evaluation of the necessity of project construction, raw materials, product plans, markets, and proce... -

Application status and trend of polylactic acid (PLA) in automobiles.

At present, the main consumption field of polylactic acid is packaging materials, accounting for more than 65% of the total consumption; followed by applications such as catering utensils, fibers/non-woven fabrics, and 3D printing materials. Europe and North America are the largest markets for PLA, while Asia Pacific will be one of the fastest growing markets in the world as demand for PLA continues to grow in countries such as China, Japan, South Korea, India and Thailand. From the perspective of application mode, due to its good mechanical and physical properties, polylactic acid is suitable for extrusion molding, injection molding, extrusion blow molding, spinning, foaming and other major plastic processing processes, and can be made into films and sheets. , fiber, wire, powder and o...